최근 몇 년 동안, 환경 보호 정책의 압력 하에서, 환경 보호 수준 이하의 합성 피혁 기업이 점차 문을 닫고 있습니다., 동시에, 신소재 및 신공정 개발로, 점점 치열해지는 합성피혁 시장 경쟁, 후진 생산 능력은 점차적으로 제거됩니다., 인조가죽의 대표주자인 현재 극세사 가죽은 환경보호와, 성능 및 가격 이점, 개발 전망은 유망하다, 합성 혁신의 발전 방향이 됨.

Tracing the development process of artificial leather technology, it can be divided into three generations: one is PVC (폴리염화비닐) 인조 가죽, the other is PU 합성 피혁, and the third is microfiber synthetic leather.

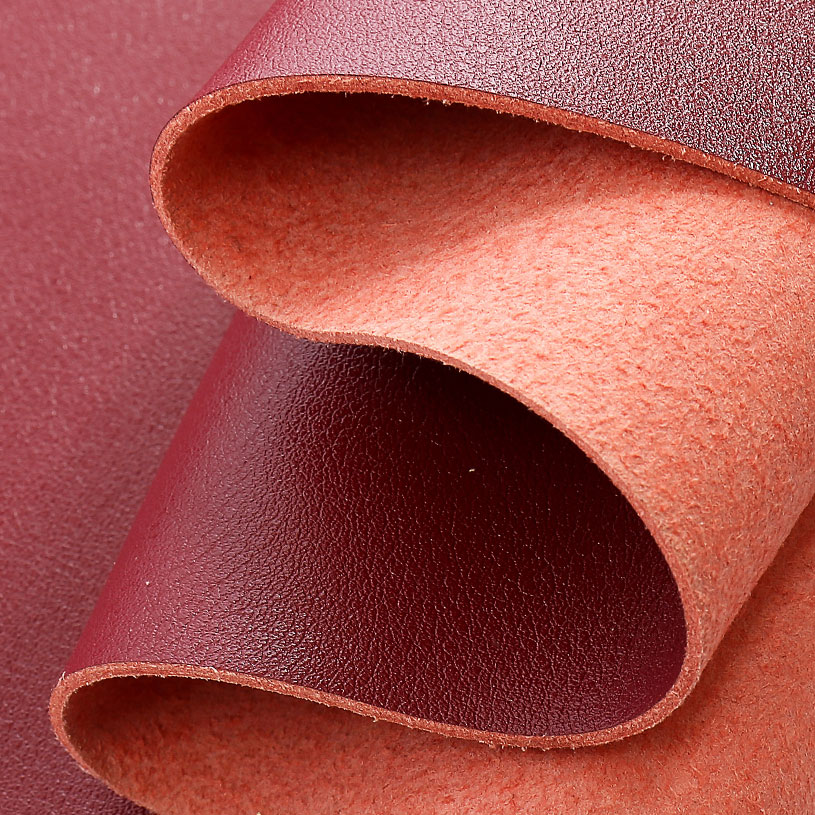

Low-end PVC leather contains chemical components that are more harmful to the human body (especially plasticizers, 기타), and the VOC content is high, and it is only used in low-end bags, 신발, balls and other fields. Synthetic leather originated in the 40s of last century after the large-scale application of polyurethane materials, with soft luster, soft feeling, strong leather feeling, good cold resistance and other advantages, widely used in clothing, furniture and high-end shoes fields.

WINIW microfiber synthetic leather, referred to as “극세사 가죽”, was developed on the basis of a full analysis of natural leather. Its production process is different from ordinary synthetic leather, and there is no peculiar smell during the production process. 내마모성이 매우 우수합니다, 내한성, breathability and aging resistance, and can almost perfectly replace high-grade genuine leather materials. The main applications include furniture, 의류, ball making, shoemaking, automotive interiors and other high-end leather consumer industries.