Wrinkle-resistant Imitation Nubuck Microsuede For Jewelry Box

1.Wrinkle-resistant.

2.Scratch-resistant.

3.Recycled materials.

- Description

- Inquiry

Introductions

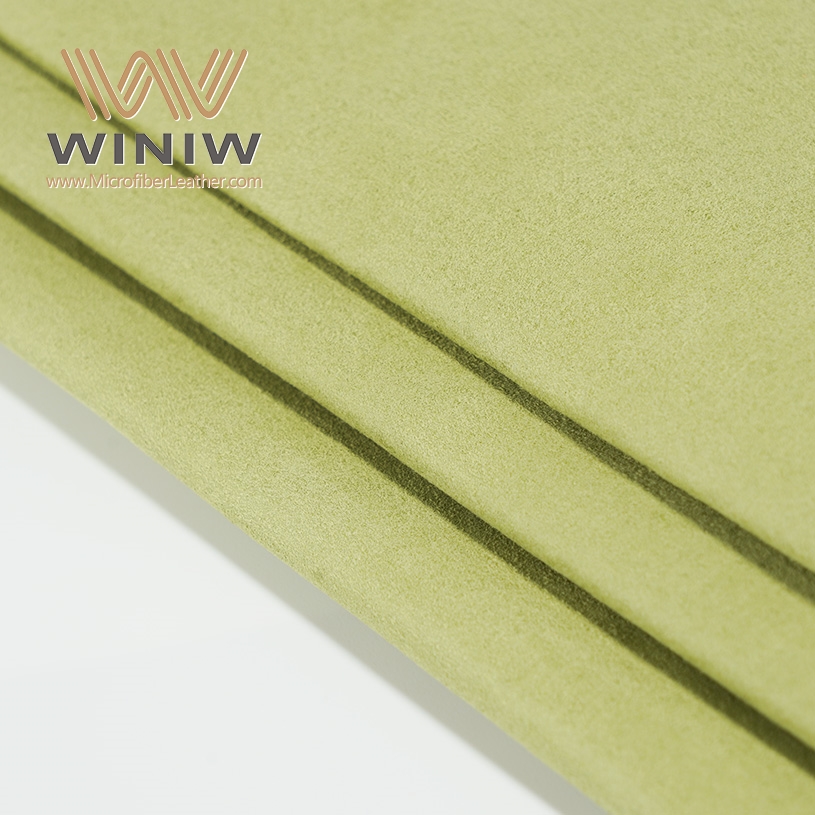

WINIW imitation nubuck microsuede leather is made of fine microfibers by an exclusive technological process. It is the best alternative that reproduces synthetically the structure of the natural leather and, as a result, it gives much more advantages: wrinkle-resistant, scratch-resistant and recycled.

Features

- Wrinkle-resistant. Through the selection of high-quality materials and advanced technology, our imitation nubuck microsuede is able to remain smooth and wrinkle-resistant, maintaining a neat, stylish appearance during use.

- Scratch-resistant. Our imitation nubuck microsuede has excellent scratch resistance and is resistant to scratches and abrasions. Whether in everyday use or in other scenarios, our leathers remain beautiful and durable.

- Recycled materials. Comparing with the common synthetic leather, its base is recycled materials. It is in line with the trend of people pursuing environmental protection.

Product Pictures

|  |  |

Specifications

| Brand Name | WINIW |

| Material | WINIW Imitation Nubuck Microsuede |

| Composition | 55% Nylon + 45% Polyurethane |

| Thickness | 0.4mm, 0.5mm, 0.6mm |

| Width | 54” |

| Color | Light green, customized colors |

| Minimum Order Quantity | 300 linear meters |

| Lead time | 15-20 days |

| Production Capacity | 1,000,000 meters per month |

| Use | Jewelry box |

| Place of Origin | Quanzhou, Fujian, China |

Applications

How is microsuede made?

Microsuede, also known as microfiber suede or ultrasuede, is a synthetic fabric that is made to resemble real suede. It is typically made from a combination of polyester and polyurethane (PU). Here is a general overview of the manufacturing process of microsuede:

1. Polymer Production: The polyester and polyurethane polymers are produced separately through a chemical process. Polyester is derived from petrochemicals, while polyurethane is typically made from a reaction between a polyol and a diisocyanate.

2. Fiber Production: The polyester and polyurethane polymers are spun into ultrafine fibers. This can be done using various methods such as melt spinning or solution spinning.

3. Bonding: The ultrafine fibers are then bonded together using different techniques like needle-punching or adhesive bonding. This process creates a suede-like texture and appearance.

4. Finishing: The microsuede fabric goes through various finishing processes to enhance its look and performance. This can include treatments to improve softness, colorfastness, stain resistance, and water repellency.

FAQs

- What can I buy from you? Microfiber leather, PU leather, environmentally friendly recycled leather, suede leather, etc.

- Where are you located? We are in China. You are welcome to visit us.

- How long for making color lab dip? Around 3-7 days.

- Can you give me your catalog? Due to the wide variety of products, please let us know your exact requirements so that we can customize it for you.

- How about the payment terms? Usually, we accept 30% T/T in advance,70% balance payment after bulk production sample confirmed and before shipment.

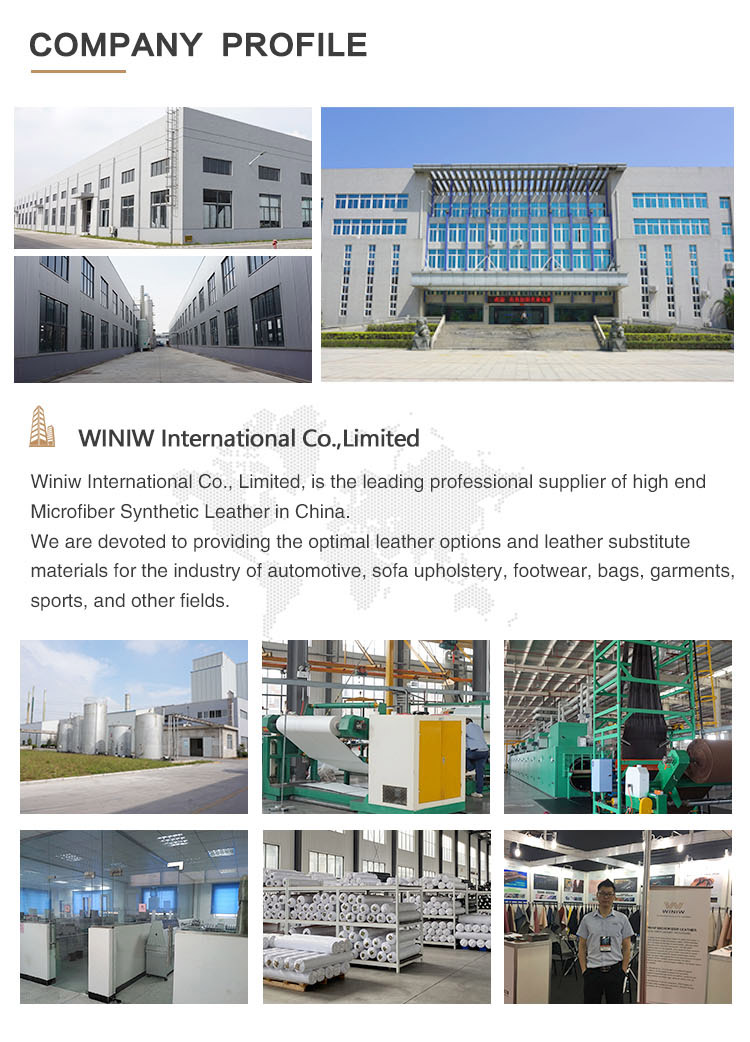

About Us

WINIW is your ideal partner for leather fabrics. Design, research and full commitment to our Clients are the keys of our worldwide success. If you need products, please feel free to contact us and we will provide warm service for you!